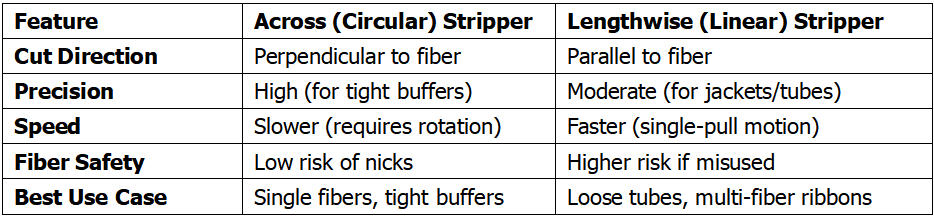

How It Works: Blades cut perpendicular to the fiber axis, creating a circular incision around the coating.

Best For:

Tight, precise stripping (e.g., 250µm or 900µm coatings).

Single-fiber cables (e.g., patch cords, pigtails).

Pros:

✅ Clean, even cuts with minimal risk of fiber nicks.

✅ Works well with tight-buffered fibers.

Cons:

⚠ Not ideal for loose-tube cables or thick jackets.

⚠ Requires adjustment for different coating diameters.

Example Tools:

Jonard FCS-2 (adjustable for 250µm–3mm coatings)

Miller FS-2 (dual-blade for precise stripping)

2. Lengthwise (Linear) Fiber Strippers

How It Works:

Blades cut parallel to the fiber axis, splitting the coating lengthwise (like peeling a banana).

Best For:

Loose-tube cables or multi-fiber ribbons.

Thick jackets (e.g., 3mm–6mm OD cables).

Pros:

✅ Faster stripping over long cable segments.

✅ No need to rotate the tool (good for confined spaces).

Cons:

⚠ Higher risk of fiber damage if misaligned.

⚠ Less precise than circular strippers for tight buffers.

Example Tools:

FiberFox LS-2 (linear blade for ribbon fibers)

Klein Tools VDV826-210 (lengthwise jacket stripper)

✔ Adopts the new 70-degree blade, make cable stripping more effort-saving.

✔ Adopts a new type notch-wheel to strengthen the grip and avoid a skid while stripping the cable.

✔ Has a crosswise stripping function.

✔ The new dial patch is clearer.

✔ The clamped knob and spin-cap improvement is more convenient when in use.

✔ Equipped with a hexagonal spanner, making the blade changing more convenient by the user.

© 2024-2026 ARTIC FIBER OPTIC CO.,LTD. All Rights Reserved.