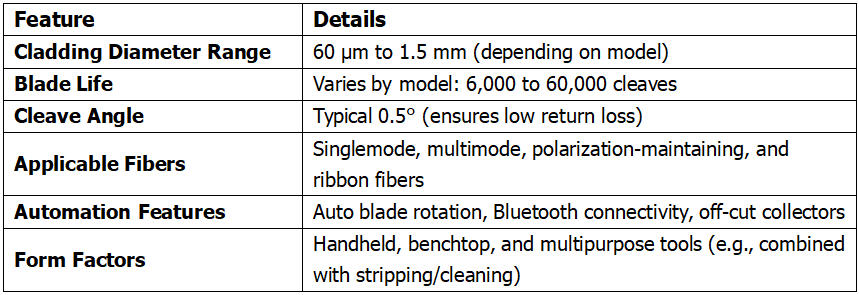

A Fiber Optical Cleaver is a precision tool used in fiber optic installations to cleanly cut optical fibers, ensuring a flat end face for optimal coupling or fusion splicing. The cleaving process involves scoring the fiber and applying controlled pressure to break it smoothly, resulting in minimal signal loss at connection points.

Types of Cleavers

✅ Handheld Cleavers:

Compact and portable (e.g., 58 x 98 x 47 mm, 260 g).

Ideal for field use and quick terminations.

✅ Benchtop Cleavers:

Larger and more stable (e.g., 100 x 81 x 63 mm, 440 g).

Suitable for high-volume splicing in data centers or labs.

✅ Multipurpose Tools:

Combine cleaving with stripping, cleaning, or proof testing.

✅ CO2 Laser Cuters:

Replace traditional cleaving for glass fibers and epoxy beads.

© 2024-2026 ARTIC FIBER OPTIC CO.,LTD. All Rights Reserved.