The Fiber Optical Cleaver is arguably the most critical tool for creating a successful fiber optic connection or splice. Its function is deceptively simple but requires extreme precision.

1. What is a Fiber Optical Cleaver?

A fiber optic cleaver is a tool used to precisely cut (cleave) an optical fiber to create a perfectly flat, smooth, and perpendicular end-face.

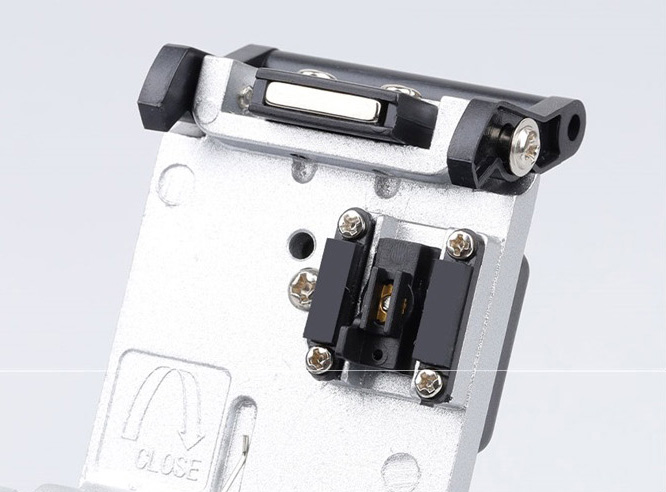

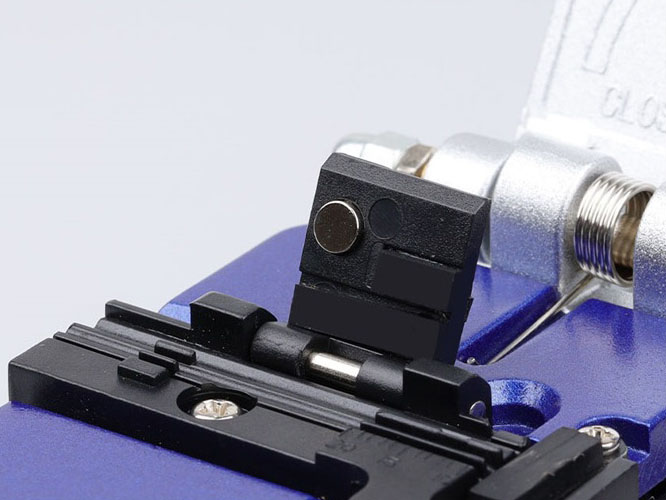

It is not a cutter that shears the fiber. Instead, it uses a controlled process of scoring (creating a microscopic scratch on the fiber's surface) and then applying tensile stress (bending or pulling) to cause the fiber to break cleanly along its crystalline structure.

Think of it like scoring a piece of glass with a glass cutter and then snapping it—but on a microscopic scale where perfection is mandatory.

✅ Cleave Angle: The most important specification. Look for <b>< 0.5°</b> for fusion splicing and high-quality terminations.

✅ Blade Life: Cleaver blades are consumables. A good diamond blade can last for thousands of cleaves. The cleaver should have a way to track usage and rotate the blade to a fresh edge.

✅ Consistency: The tool must produce the same high-quality cleave every single time.

✅ Fiber Type Compatibility: Most cleave standard SMF/MMF (125µm cladding). Ensure it works with any specialty fibers you might use (e.g., coated fibers, HCF).

✅ Durability: A cleaver is a precision instrument. It must be built to withstand the rigors of a tool bag or van.

The cleaver is used at the final step of fiber preparation, just before:

✅ Fusion Splicing: The two fibers to be spliced are cleaved and then placed into the splicer.

✅ Mechanical Splicing: The fibers are cleaved and then inserted into the splice unit.

✅ Connector Termination: For field-assembly connectors (like the FastConnect SC APC), the fiber is cleaved to a specific length before being inserted into the connector body and secured.

© 2024-2026 ARTIC FIBER OPTIC CO.,LTD. All Rights Reserved.