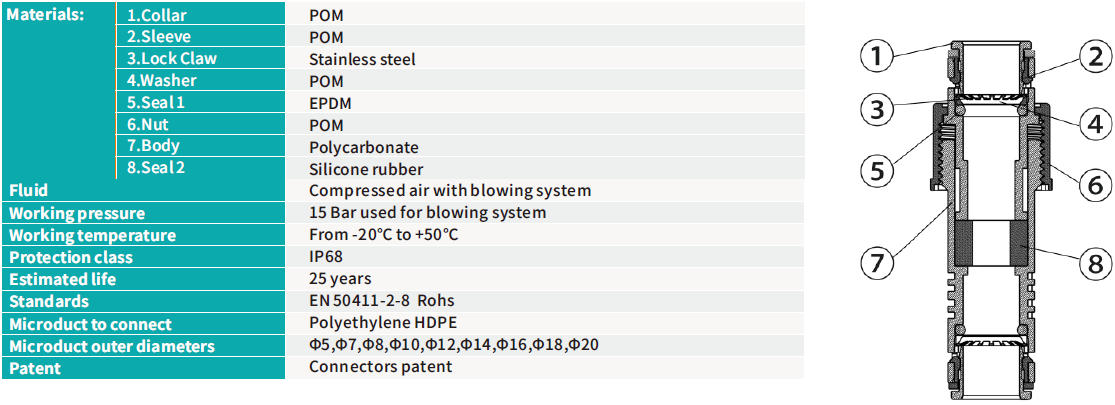

✅ Size Compatibility: Available for microduct outer diameters (OD) ranging from 4mm to 22mm, with cable accommodation ranges typically between 0.9mm to 18mm.

✅ Temperature Range: Operates effectively in temperatures from -20°C to +50°C.

Pressure Ratings:

✅ Blowing Pressure: Up to 15–25 bar for cable installation.

✅ Sealing Pressure: Typically seals against external pressures up to 0.3–0.5 bars.

✅ Certifications: Complies with standards such as EN 50411-2-8 for microduct connectors and IP68 for environmental protection.

✅ Building Entry Points: Installed at transitions where microducts enter buildings, ODFs (Optical Distribution Frames), or cabinets to prevent gas/water ingress into sensitive indoor environments.

✅ FTTx Networks: Critical for Fiber-to-the-Home (FTTH) and Multi-Dwelling Unit (MDU) deployments, ensuring end-to-end network integrity.

✅ High-Risk Environments: Essential in areas prone to gas leaks (e.g., industrial zones) or flooding, where environmental hazards could compromise network functionality.

✅ Direct Burial and Underground Ducts: Some models are designed for underground use, though others may require additional protection for direct burial applications.

© 2024-2026 ARTIC FIBER OPTIC CO.,LTD. All Rights Reserved.