What Problem Does It Solve? (The Need for Reinforcement)

Standard end caps are effective for basic protection, but they can be susceptible to:

✅ Dislodgement: Being accidentally knocked off during handling, backfilling, or in congested underground vaults.

✅ High-Pressure Moisture: In areas with high water tables or flood risk, water pressure can force its way past a standard seal.

✅ Rodents and Vermin: Animals may be able to chew or pull out a standard cap.

✅ High Internal Pressure: During pressure testing of the duct system, a standard cap could be blown off.

The Reinforced End Cap is engineered to solve these problems, providing a virtually permanent and fail-safe seal.

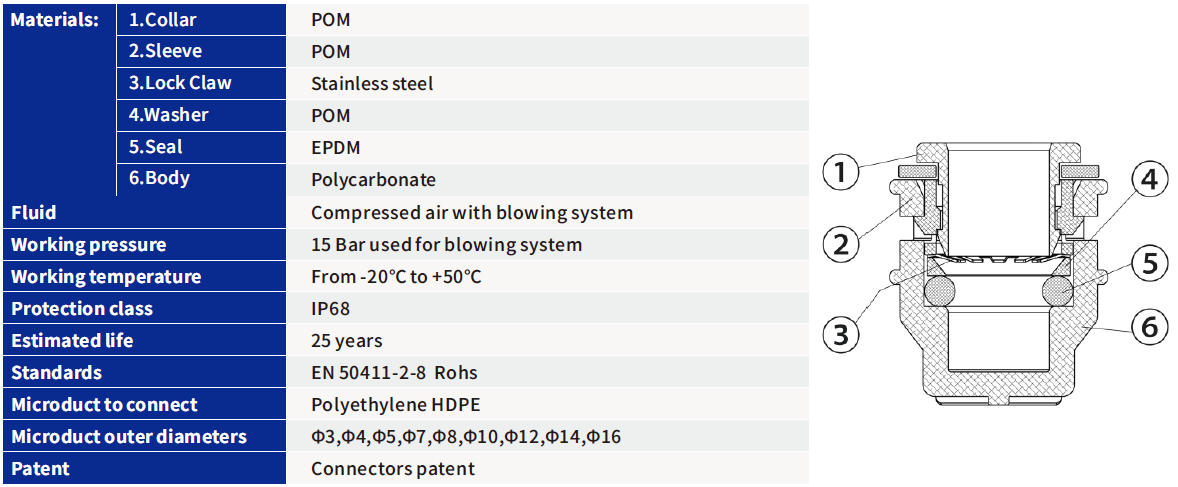

✅ Mechanical Locking Mechanism: This is the core of its "reinforced" status. Common mechanisms include: 🔹 Stainless Steel Clamp: A metal band around the cap that is crimped with a special tool, creating immense radial force that locks the cap onto the duct.

🔹 Internal Barbed Gripping Rings: Sharp, angled ridges that bite into the outer jacket of the microduct when inserted, making it extremely difficult to pull out.

🔹 Threaded Designs: Some designs screw onto a pre-attached collar that is first permanently fixed to the duct.

✅ Superior Sealing System:

🔹 Multiple O-Rings: Utilizes several rubber O-rings to create redundant sealing barriers against moisture and gas.

🔹 Advanced Gel Seals: Often filled with a thick, water-blocking gel that completely fills any potential pathways for moisture, even under hydrostatic pressure.

✅ Pressure Rating: Specifically designed to withstand both internal positive pressure (from air testing) and external negative pressure (from vacuum).

✅ High-Durability Material: Constructed from extra-tough, chemical-resistant, and UV-stabilized engineering plastics (like high-grade Nylon) to prevent cracking or degradation over time.

Tamper Evidence: Once installed and crimped, they are very difficult to remove without obvious damage, providing evidence of tampering.

How and Where Is It Used?

Reinforced end caps are deployed in scenarios where failure is not an option and the highest level of protection is required:

✅ Direct Burial: Protecting duct ends in underground trenches where they are exposed to soil pressure, groundwater, and potential rodent activity.

Submarine/Aquatic Installations: Sealing ducts that run under rivers, lakes, or in flood zones where they are subjected to constant and significant hydrostatic pressure.

✅ Network Terminal Points: Sealing the ends of main feeder ducts in manholes or at the base of poles where network integrity is most critical.

✅ Long-Term Storage: On ducts that may be installed ("stood") months or years before fiber cable is blown through them, ensuring they remain perfectly sealed during this dormant period.

✅ Gas-Blocked Duct Systems: In regions where methane or other gases can permeate the soil, these caps provide a gas-tight seal to prevent gases from entering the building through the duct.

Installation typically requires a specific crimping tool to apply the correct force to the stainless steel clamp, ensuring a consistent and reliable seal.

© 2024-2026 ARTIC FIBER OPTIC CO.,LTD. All Rights Reserved.