Talk to us

Talk to us

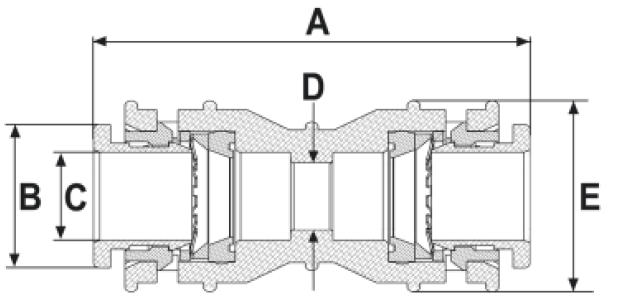

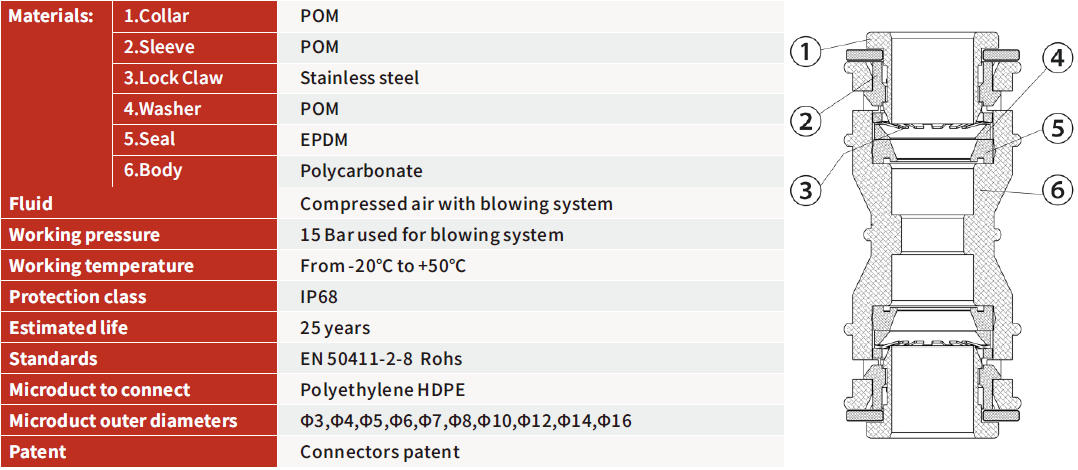

Reinforced Mechanical Lock: This is the defining feature. It often includes:

Internal Barbed Gripping Rings: Sharp, angled ridges that bite into the outer jacket of the microduct when inserted, making it extremely difficult to pull out.

External Stainless Steel Clamp or Band: A metal band that is tightened around the connector body with a special tool, applying immense radial pressure to crimp the connector onto the ducts, creating a permanent, ultra-strong bond.

✅ Superior Sealing: Integrated O-Rings: Multiple rubber O-rings are housed inside the connector. When the duct is inserted, these rings compress to form a powerful water-tight and air-tight seal.

✅ Gel Seals: Some high-end models may be filled with a water-blocking gel that provides an exceptional barrier against moisture ingress.

✅ Smooth Bore: The internal pathway of the connector is perfectly smooth and aligned with the inner diameter of the microduct. This is essential to prevent snagging the fiber cable during pulling or blowing and to maintain laminar airflow.

✅ Durable Material: Manufactured from high-impact, corrosion-resistant, and UV-stabilized materials like Nylon or Polypropylene to survive harsh underground or aerial environments.

✅ Color Coding: Often available in standard microduct colors for easy identification of duct size within a bundle.

© 2024-2026 ARTIC FIBER OPTIC CO.,LTD. All Rights Reserved.