What is Thermal Label Spacer Tape?

Thermal Label Spacer Tape (also known as Foam Spacer Tape or Cushion Tape) is a specialized type of label material designed for applying durable, legible labels to uneven, textured, or curved surfaces.

It is a multi-layered tape, typically consisting of:

✅ A top layer: A printable facestock (often durable polyester or vinyl) that receives the printed text/graphics.

✅ A middle "spacer" layer: A compressible foam core. This is the key differentiator.

✅ A bottom layer: A strong adhesive backing.

Unlike a standard label that is thin and rigid, the foam spacer layer allows the label to compress and conform to irregular shapes, ensuring the adhesive makes full contact with the surface.

✅ Exceptional Conformability: Fills grooves and contours for maximum adhesive contact.

✅ Durability: The foam core acts as a shock absorber, providing abrasion and tear resistance.

✅ Permanent Adhesion: Prevents edge-lift and peeling, even on challenging surfaces.

✅ Environmental Sealing: Helps keep moisture and contaminants out from under the label.

High-Temp Resistance: Many spacer tapes are made with materials that withstand soldering temperatures and other industrial processes.

Thermal Spacer Tape solves this:

✅ You apply the label to the uneven surface (e.g., a ribbed cable).

✅ You apply pressure.

✅ The foam spacer layer compresses into the grooves and valleys of the surface.

✅ This allows the adhesive to make complete contact across the entire application area, not just the high points.

The result is a bubble-free, seamless bond that will not peel or lift at the edges.

How It Works: The "Spacer" Principle

Imagine trying to put a sticker on a corrugated cardboard sheet. A flat sticker would only make contact with the raised ridges and would quickly peel off from the valleys.

Primary Uses and Applications

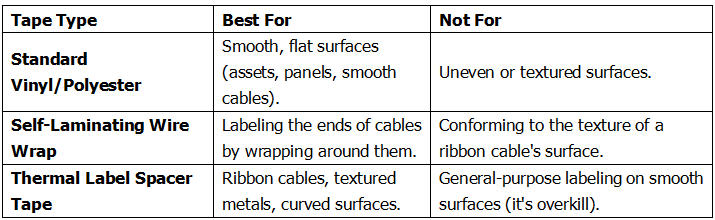

This tape is essential in industries where standard labels fail. Its most famous application is:

✅ Ribbon Cables (FFC - Flexible Flat Cables): This is the #1 use case. The tape conforms perfectly to the tiny ribs and grooves of the cable, creating a permanent, flat label.

✅ Textured Surfaces: Brushed metal, pebbled plastic, rough powder coats.

✅ Curved Surfaces: Wiring harnesses, tubes, small-diameter cables.

✅ Industrial Components: Labeling irregularly shaped connectors, relays, and devices.

✅ Without Spacer Tape: Labels bridge over gaps, trap dirt, and peel easily.

✅ With Spacer Tape: Labels lie flat, are sealed from the environment, and are extremely durable.

© 2024-2026 ARTIC FIBER OPTIC CO.,LTD. All Rights Reserved.